Compression testing

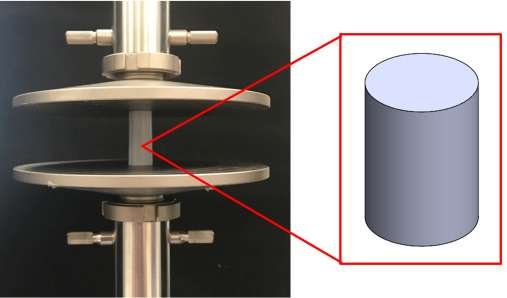

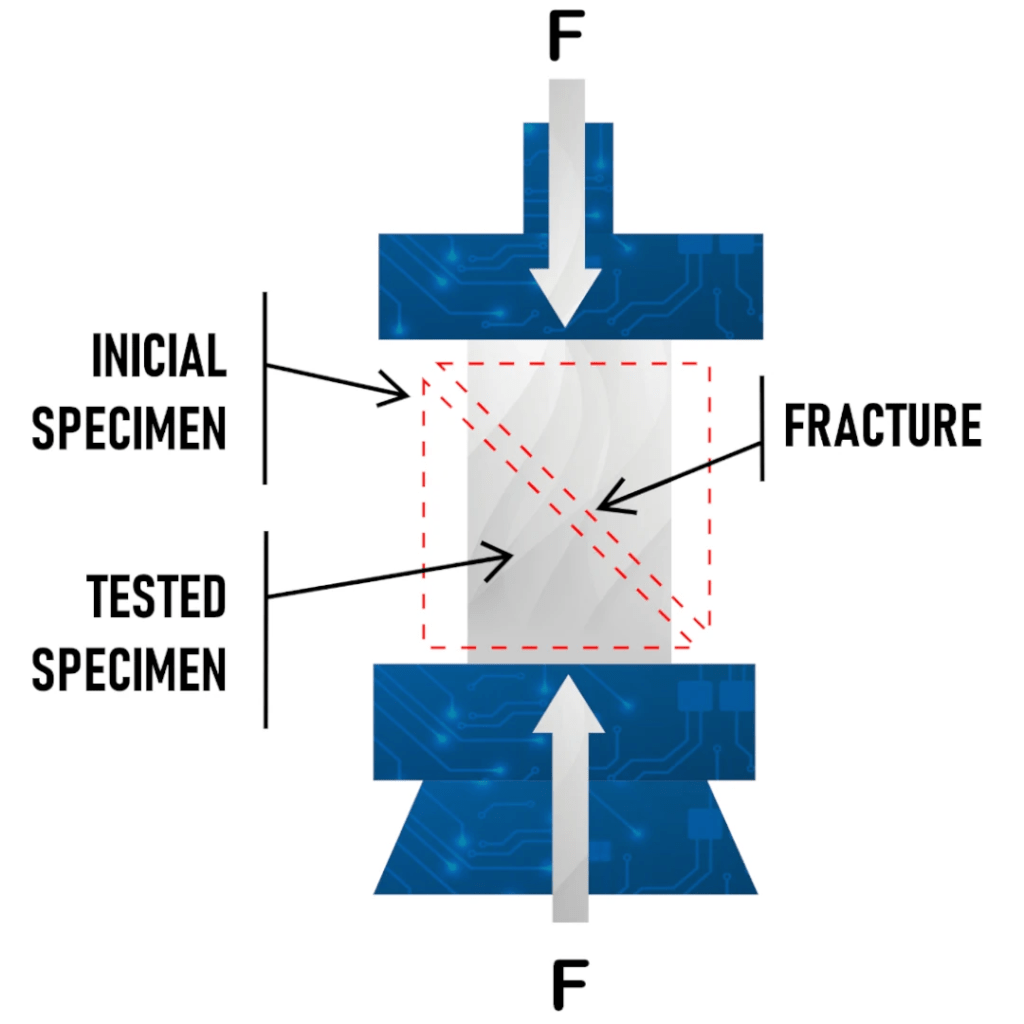

The compression check is a key technique in mechanical evaluation, along tensile and flexural exams in substances trying out. This system involves making use of a compressive pressure to a specimen, typically shaped as a cuboid or cylinder, the use of specialized fixtures or platens on a regularly occurring trying out device. The test assesses how substances respond to crushing hundreds, providing essential statistics on homes which includes the elastic restriction, yield factor, and compressive electricity.

Compression testing system

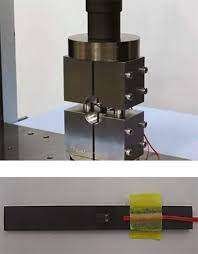

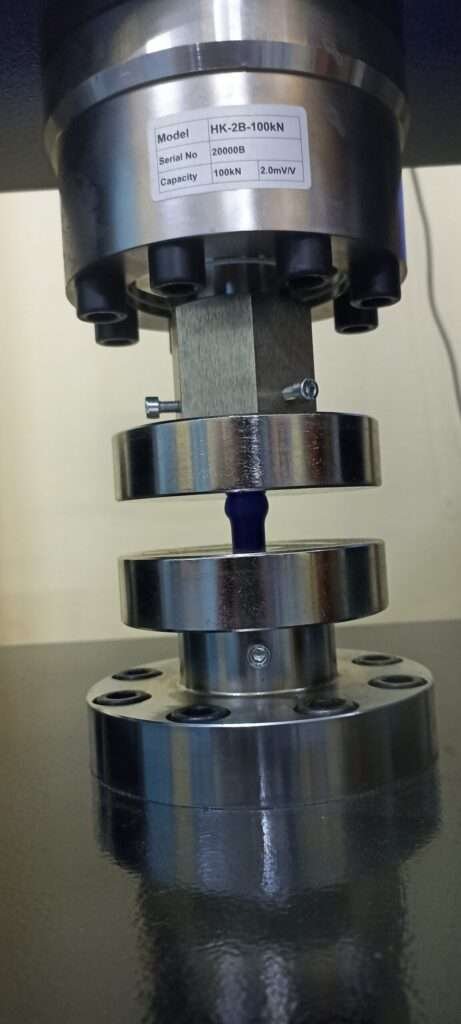

carrying out a compression test entails the usage of a compression testing machine ready with load cells, software, and specific platens. throughout the trying out process, engineers apply stress to the specimen using platens and furnishings tailored to the cloth kind and checking out requirements. as an instance, one of a kind platens can be utilized for trying out rigid plastics, foams, or metals.

once the compression test begins, the device applies a controlled pressure to the specimen whilst collecting information in real-time. The resulting strain-stress diagrams offer valuable insights into the fabric’s conduct under compression.

Engineers examine these diagrams to extract crucial residences inclusive of elastic modulus, yield energy, and compressive power. through deciphering the stress-strain curves, they can discover key cloth traits, which includes yield factors, deformation behavior, and failure modes. This analysis is essential for comparing the cloth’s performance and figuring out its suitability for its intended application.

Purpose and Importance of Compression Testing

Compression checking out is crucial across diverse industries for comparing cloth integrity, safety, and performance. producers depend on compression exams to evaluate substances, components, and merchandise at extraordinary tiers of manufacturing. This testing helps in deciding on suitable materials for brand spanking new packages, ensuring product best, and maintaining compliance with enterprise requirements.

Compression checking out optimizes layout, complements performance, and improves product reliability. it’s miles specially important in sectors inclusive of automobile, aerospace, construction, and clinical gadgets. with the aid of figuring out material weaknesses early in the system, compression testing plays a great function in making sure product sturdiness, leading to vast value financial savings and overall enhancements in product first-class.