Provided with sufficient time and thermal stress, materials sometimes fail below maximum ratings. Such deformation at loads less than yield-strength is termed creep and, left unbridled, will continue to progressive failure via rupture.

Such microscopic deformation at loads less than ideal maxima subtly threatens device integrity and user safety. A stress rupture and creep testing lab might determine the material loading such that field performance may be characterized in order to benefit the end-user and the manufacturer.

Stress Rupture

The test determines the time to produce failure while the material is under constant load at a constant temperature. The test measures the time to rupture and the influence of temperature on long-time load-carrying characteristics. The reported results are useful where the dimensional tolerances of the application are unimportant but rupture must not occur. Stress rupture testing is very similar to creep testing, but with higher stresses.

Creep

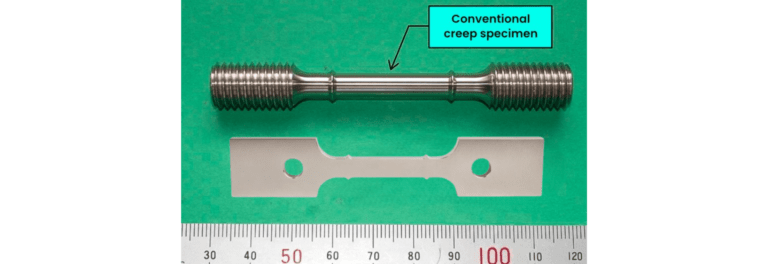

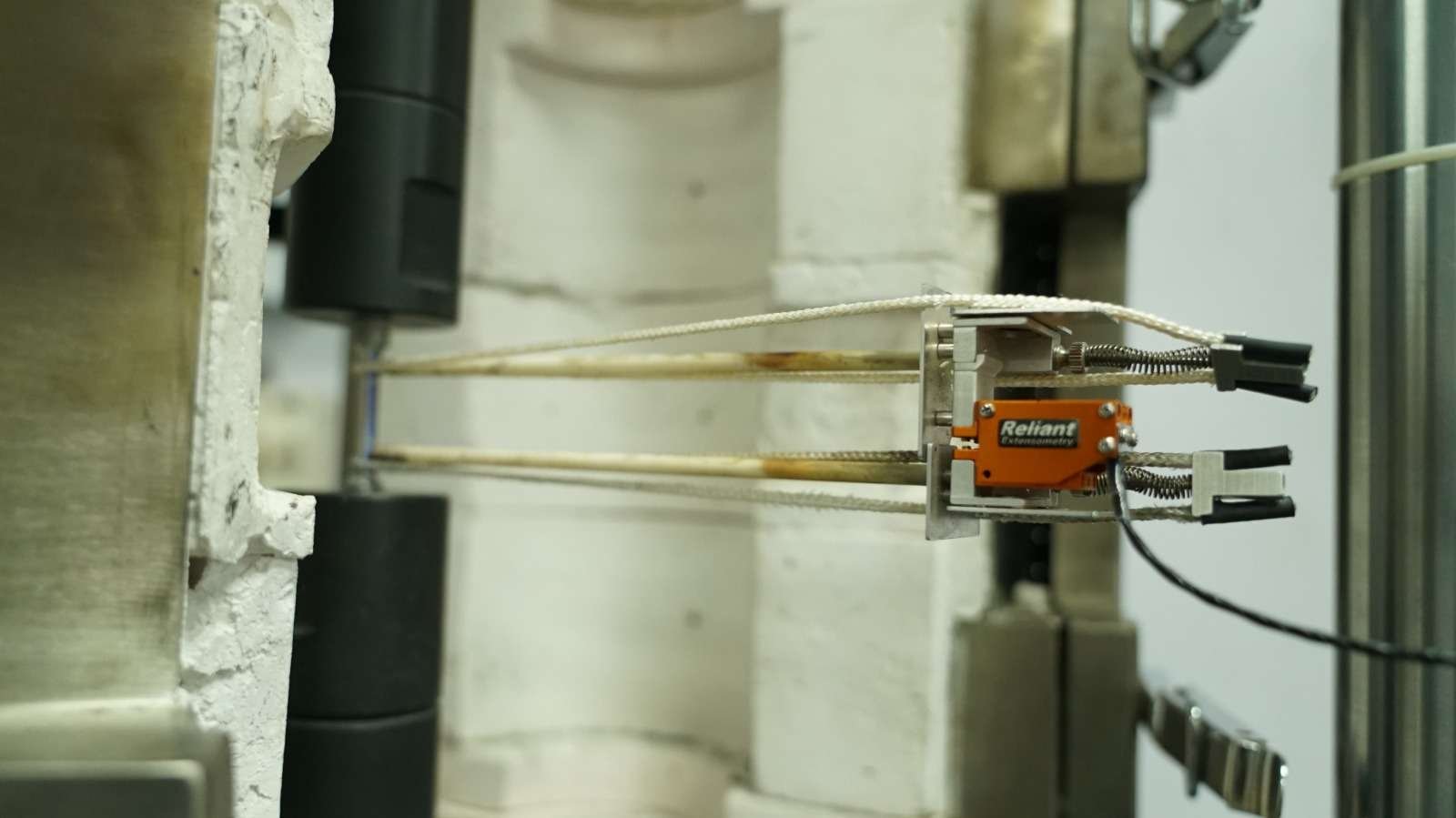

Creep test measures dimensional changes to a specimen under high-temperature exposure after applying a constant load below its yield strength and is time-dependent. An extensometer measures the elongation or deformation of a specimen, thus calculating how a component or part will change during service. Creep testing is a very critical tool when dimensional control is an issue at high temperatures or while determining time-to-failure.

Capabilities

Fully automated machines that perform the tests at temperatures up to 2000°F.

Reliable temperature control using calibrated thermocouples attached to the test specimens.

Automatically adjusted load at various time intervals for efficiency.

Nadcap and A2LA ISO/IEC 17025 accredited and ASTM-compliant.

Specimen machining: Smooth, notched, combination, or flat

Specifications: ASTM E139, ASTM E292, NASM-1312-10

Approvals:

GE Aviation

P&W qualified as a commercial laboratory for Reference MCL Manual Section Appendix 56: Code 3 stress-rupture testing

TTS is a leader in the circles of Material Testing Laboratories.

A stress rupture and creep testing lab will give fundamental material characterizations for real-world load conditions. These high-temperature tests ensure that the material can withstand significant thermal stresses before failure and accelerate aging of samples to provide a relatively rapid turnaround of test results.

Turnaround time to customer test requirements, at TTS, is short. Our state-of-the-art lab is staffed by field experts and equipped with sensitive equipment, providing our customers with a one-stop solution to test all their materials and product parameters.