J-integral testing, commonly referred to as J1c testing, is a fracture toughness test that evaluates a material’s resistance to crack initiation and propagation under stress. This test specifically measures the critical value of the J-integral, J1c, a parameter that describes the energy rate associated with crack growth in a material, particularly under conditions where plastic deformation is significant.

Unlike linear elastic fracture mechanics, which primarily addresses brittle materials, J1c testing is well-suited for ductile materials where plasticity at the crack tip cannot be ignored.

Purpose and Application

J1c testing is essential in industries where components are subjected to high stresses and must resist crack growth for safety and reliability, such as in aerospace, automotive, structural engineering, and pressure vessels.

By determining the J-integral, engineers can understand how much energy a material can absorb before cracks start to grow, thus aiding in the design of materials and structures that can endure demanding environments.

Test Procedure

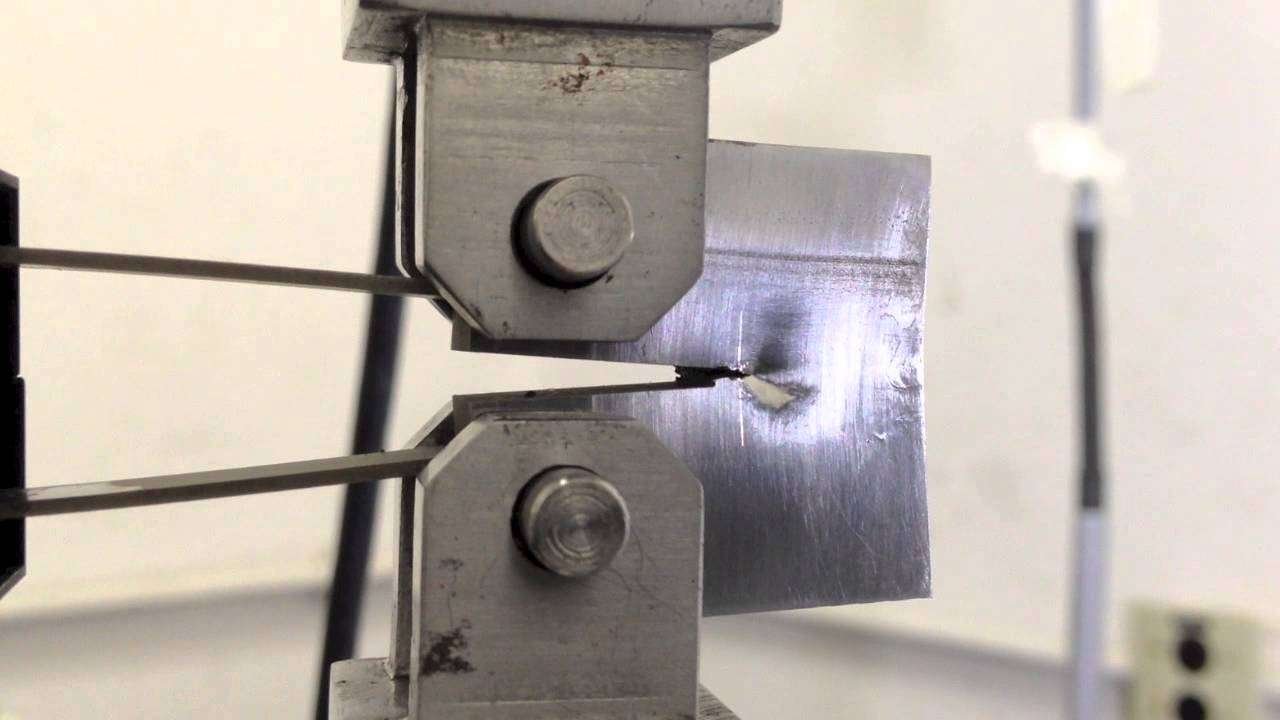

1. Specimen Preparation: Typically, a compact tension (CT) or single-edge notched bend (SENB) specimen is used. The specimen geometry and size are standardized to provide consistent and comparable results.

2. Loading: The specimen is subjected to a controlled loading process in a testing machine, where force is gradually applied to introduce stress at the crack tip.

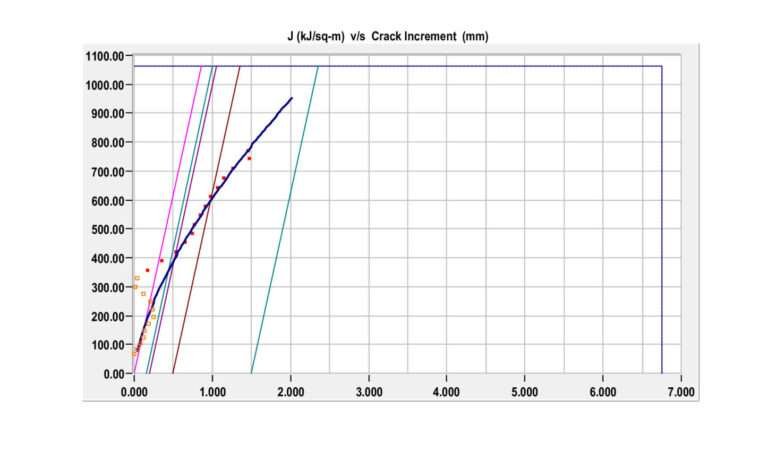

3. Measurement of Load and Displacement: As the load increases, the load-displacement data is recorded. This data is used to calculate the J-integral value by integrating the area under the load-displacement curve.

4. Calculation of J1c: The J1c value is obtained at the point of crack initiation, which can be determined by observing a specific deviation in the load-displacement curve or using other compliance-based techniques. Standards like ASTM E1820 provide detailed guidelines on how to calculate J1c and interpret the results.

Standards

ASTM E1820 / JIC Testing and More

In a test to ASTM E 1820, a steadily increasing load with intermittent partial unloading is applied in order to measure the crack length as the test proceeds.

Because this method takes measurements at every point along the test, it provides much more information about the way the material behaves as the crack opens.

Often, it is possible to obtain valid results where it would be impossible or entirely impractical with a KIC test.