K1ctesting, or fracture toughness testing, measures a material’s resistance to crack propagation. K1c, known as the “plane-strain fracture toughness,” represents the critical stress intensity factor at which a crack in a material will start to grow uncontrollably. This value is particularly important for understanding a material’s behavior in applications where cracking could lead to failure under load.

Often, it is as crucial to know how and why material fails as when. Crack propagation in 3D bodies will be proportional to the force applied and the size/shape of the flaws, but loading is complex, with a stress-strain matrix developing which depends on the distance in space between the applied loading and material flaws, the material’s performance in tension vs. compression, and a host of other variables. Fracture toughness testing tries to quantify performance by breaking materials with increasing loading forces, then looking into the propagation of cracks through failure.

Why K1c Testing is Important

K1c is a key material property in safety-critical industries, including aerospace, automotive, and civil engineering, where the structural integrity of materials under stress is paramount. The K1c value allows engineers to determine a safe stress level or crack length at which a material can operate without failure.

In this test, fracture toughness is the measure of how big a material is able to resist the extension of a developing crack by an increasing load. If a specimen possessing an existing crack is subjected to a rising tensile load during fracture toughness testing, there is sufficient energy in the deformation-in terms of combined load and displacement-to reveal the material’s resistance to further crack extension. Fracture toughness is an important property in design applications since the occurrence of flaws can never be completely avoided. Flaws may appear as cracks, voids, inclusions, weld defects, or design discontinuities. The fracture toughness test also finds its value for the purpose of determining if failure of the component is dangerous in case a flaw is revealed in an existing structure.

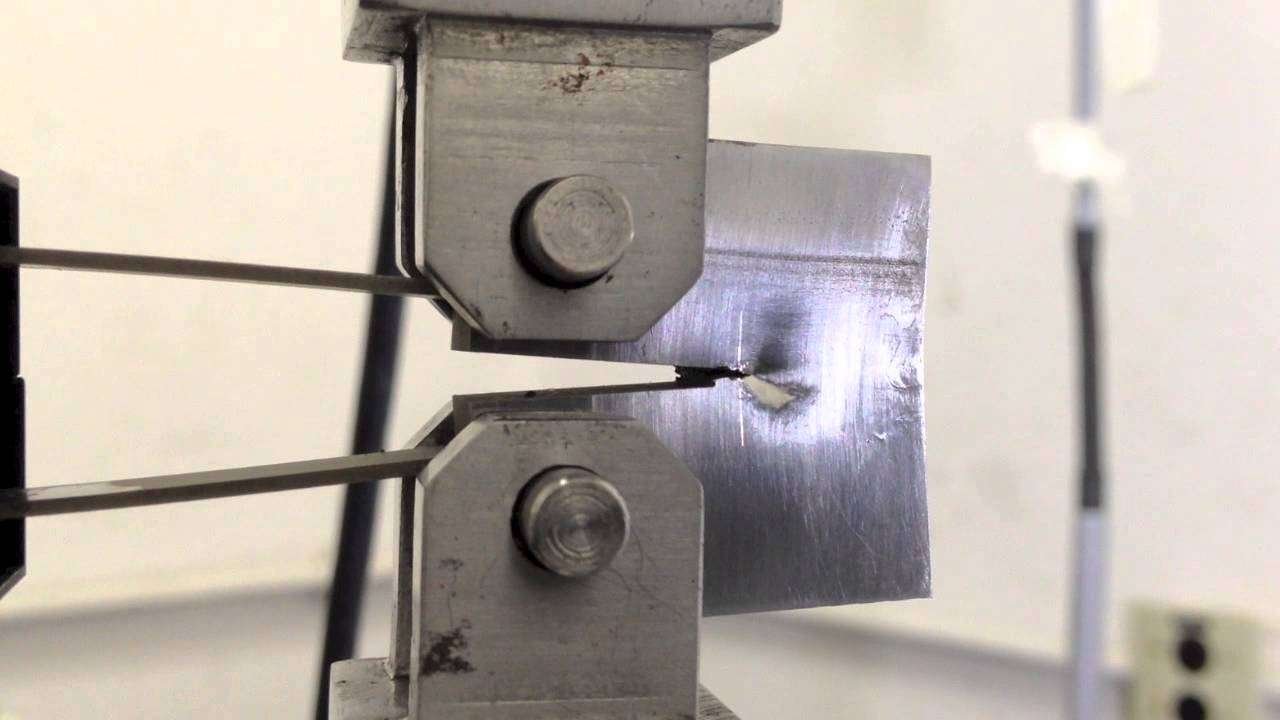

K1c testing typically follows standards such as ASTM E399. The test is performed by preparing a specimen with a notch or pre-crack, which ensures that any stress applied will act as it would on a real crack. The sample is then subjected to a controlled load, increasing until the crack propagates in a stable manner. This point marks the K1c, which is measured in units of MPa√m (megapascal root meter).

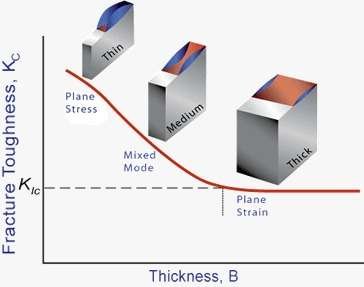

The test conditions aim to create a “plane strain” state, where the thickness of the specimen is enough to prevent out-of-plane stresses, isolating the pure fracture toughness of the material. As a result, K1c provides a conservative measure of fracture toughness, meaning it gives a lower-bound estimate, suitable for critical applications.

Applications of K1c Testing

1. Pressure Vessels and Pipelines: To prevent catastrophic failures under high pressures.

2. Aircraft Structures: Ensuring materials can withstand high-stress conditions without fracture.

3. Bridges and Buildings: For structural materials that must resist cracking under environmental and loading stresses.

Standards

ASTM E399 / KIC Test

ASTM E399 describes the fracture toughness test as one in which a continuously increasing load is applied to the specimen, and critical stress intensity KIc is determined. This method is thus termed the KIC, KIC, or K1C fracture toughness test. It is widely used in standards of the aerospace industry.