Our lab is fully equipped with specimen preparation

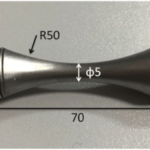

Specimens for fatigue tests are carefully machined to meet specific requirements for their dimensions and surface finish. The preparation of the specimens is critical for fatigue testing, and the following steps are involved:

Machining: The specimen should be machined to minimize the chances of residual stresses or machining marks on the surface.

Grinding: Before polishing, the specimen should be low-stress ground.

Polishing: The specimen should be polished longitudinally to remove any machining marks.

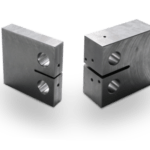

Machining Test Specimen

Complete Example Machining Capabilities: Our in-house machine shop is prepared with imaginative innovation and staffed by exceedingly gifted administrators. From metal crude materials to added substance fabricated parts, we can plan examples for a wide run of materials, counting solidified steels, nickel-base amalgams, and a few plastics.

Fast Turnaround: We get it the significance of speed in your testing forms. Our 12,000 sq. ft. machining range is planned for high-speed example arrangement, guaranteeing fast extend completion.

Unmatched Ability: Our specialized specialists are accessible for meeting to meet challenging determination prerequisites. We can work from special cut plans, giving custom fitted arrangements for your particular needs.

Test Specimens Summary

Quality You Can Trust

Selecting TTS means collaborating with a skilled provider committed to providing excellent specimen preparation. TTS is aware that precise test findings depend on well-machined specimens. We guarantee that every project satisfies the highest quality requirements by adhering to industry specifications including ASTM, AWS, ISO, EN, DIN, JIS, and NACE. Every aspect of our specimen machining services is painstakingly recorded.

Specimen Preparation Process

As specified in a necessary specification or specified in a drawing that comes with the order, test specimens are rough cut to length by sawing from a precise place on the sample material or part. Technicians chop the material into a manageable size in this step, usually in proximity to the finished specimen. Etching can be used to determine the location of the center line or heat-affected zone in the case of welds. A Maxiem waterjet cutting system is part of TTS sawing apparatus.

In order to center and turn a part in diameter, a lathe rotates it against a stationary cutting tool. Since rough-cut test specimens are often square, lathing is necessary for all round specimens, including tensile, stress rupture, Gleeble, Jominy, rotating beam, and fatigue. When fixturing on test equipment is necessary, turning threads the ends and shortens the gage length in addition to further refining specimen measurements.

Material is removed during milling by passing a workpiece through a rotating cutter with many teeth. The benefit: Milling produces a wide variety of shapes, and machined surfaces can be flat, angular, or curved. Test specimens such as flat tensile, stress rupture, and hardness are precisely machined by this procedure. Additionally, certain corrosion specimens and side, face, and root bend specimens for weld qualifications are available. Charpy specimens can also be further refined using milling for the following step: grinding.

Material is removed during milling by passing a workpiece through a rotating cutter with many teeth. The benefit: Milling produces a wide variety of shapes, and machined surfaces can be flat, angular, or curved. Test specimens such as flat tensile, stress rupture, and hardness are precisely machined by this procedure. Additionally, certain corrosion specimens and side, face, and root bend specimens for weld qualifications are available. Charpy specimens can also be further refined using milling for the following step: grinding.